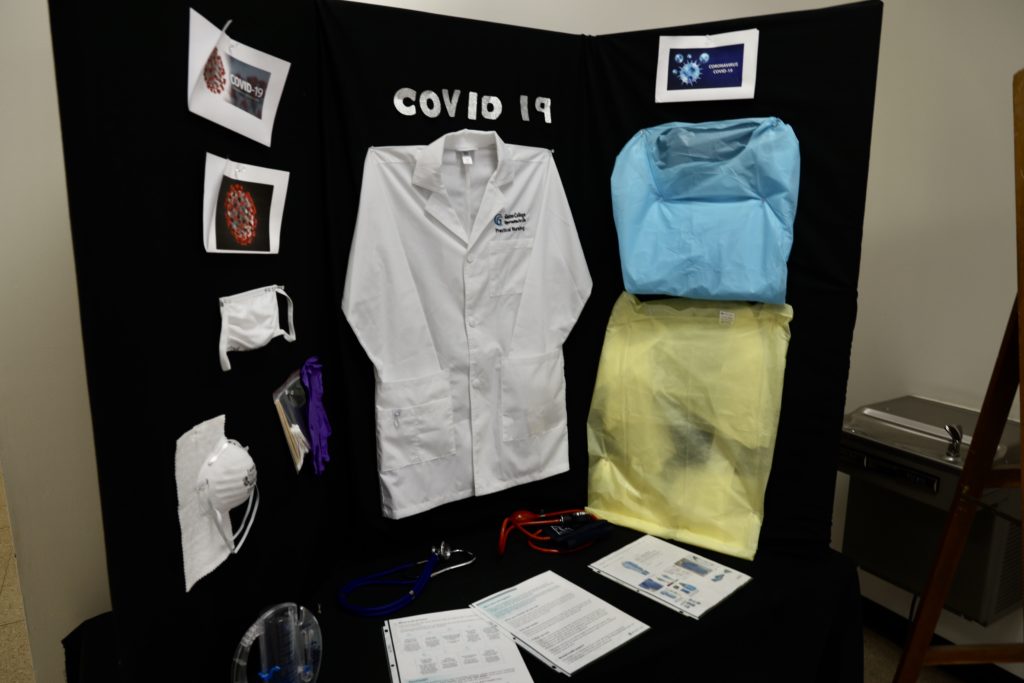

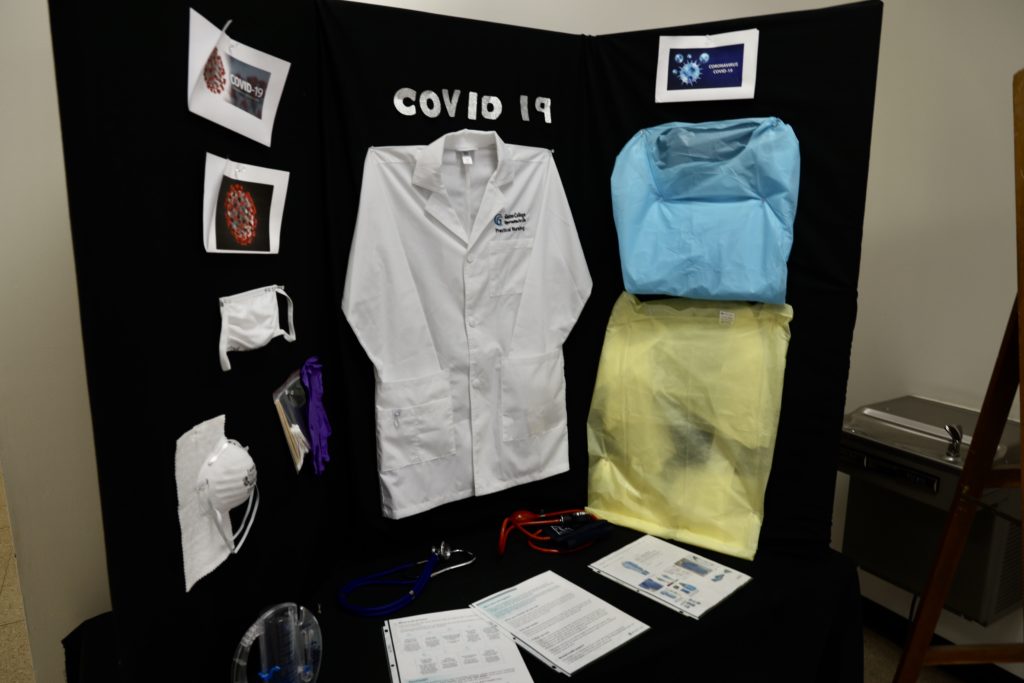

The demand for personal protective equipment (PPE) has increased significantly during the pandemic. There are many PPE manufacturers abroad, but there are also factories in North Carolina with the capacity to create these critical products.

Many international PPE manufacturers, like those in China, are able to create these health care products at a price that domestic factories struggle to compete with. Gaston College and Catawba Valley Community College have teamed up to lead a new innovative partnership to manufacture medical supplies locally.

The goals of the partnership include:

- Providing locally made, reusable PPE for the medical community

- Creating small business opportunities for local manufacturers

- Helping close the workforce skills gap in the region

The partners

This isn’t the first time Gaston College and Catawba Valley Community College have joined forces in partnership. The service regions for both schools border each other. Gaston College serves Gaston and Lincoln counties. Catawba Valley serves Catawba and Alexander counties.

“We just believe we have an opportunity to expand our expertise at each institution and share that with one another, and to create partnerships across county lines,” said John Hauser, president of Gaston College.

Historically, both schools have worked together to tackle regional workforce needs in their neighboring communities. This partnership aligns their combined services with the needs of the region. Hauser is looking forward to demonstrating the value of community college partnerships in helping tackle the workforce skills gap the state is facing.

“We’re closing that workforce skills gap as a region,” Hauser said.

The other partners for the project include:

- The city of Conover

- Gaston County

- The private sector

“This partnership involving public and private sectors will serve as a launch pad for prototyping and testing reusable personal protective equipment (PPE) products for entrepreneurs and existing manufacturers in response to the COVID-19 pandemic,” said a press release from Catawba Valley Community College.

The project, the funding, and the timeline

Recently, the NC General Assembly passed COVID-19 relief legislation, House Bill 1105, that Gov. Roy Cooper signed into law. Part of the legislation allocated federal funds for reusable PPE. A total of $14.3 million will go to this partnership project from the legislation.

Nine million of that $14.3 million is going to the city of Conover, which will use the funding to build a facility to provide rapid prototyping of products, a textile sourcing library, and house testing labs. The rest of that $9 million will be used for a “cleaning room uplift for the facilities at the MSC,” (Manufacturing Solutions Center) and will include logistics for a pilot of a rapid prototyping line that will create PPE products and train the workforce entering the industry.

The remaining $5.3 million will go to Gaston County to build an Incubator and Extrusion Center for Advanced Fibers for Gaston College’s Textile Technology Center (TTC).

“Since the pandemic started, we were able to quickly turn around the testing of these products and develop new prototyping for products,” Hauser said.

The products Hauser is speaking of are medical-grade face shields, protective gowns, and the swabs used for COVID-19 testing. The partners are currently working with nine different sewing companies to find fabrics and have created a database of companies that have the capacity to manufacture reusable PPE. The products have to meet certain requirements in order to be fit for use in the medical community. According to Hauser, the products must meet standards set by the Occupational Safety and Health Administration.

“These are the ones that are used by doctors and nurses, those front line essential workers in our medical facilities,” Hauser said.

The Textile Technology Center (TTC) at Gaston College can currently produce fiber that can be used for PPE, but with several limitations. The new facility will help the college improve their technology offerings and overall production in advanced fiber development. Small businesses will then be able to use these developments in their manufacturing of PPE locally and regionally. In addition, TTC will manufacture a product that will go directly into PPE diagnostic testing kits to be used by customers. Due to strict confidentiality around the development of said product, the college was not able to give additional detail.

The hope is that the buildings being constructed for this project on Gaston and Catawba’s campuses will be up and running within 12 to 16 months of breaking ground. Hauser is particularly excited about the piece of the collaboration that will allow them to create a new targeted industry skill certification. He thinks this new partnership and impending skill certification will help tackle myFutureNC’s attainment goal: that by 2030, 2 million North Carolinians ages 25-44 will have a high-quality credential or postsecondary degree.

“We know that together, we create success and we can create a model for an accelerated pathway to meet our current emerging needs for our economy,” Hauser said.

You can read more about the new partnership here.